NEWS

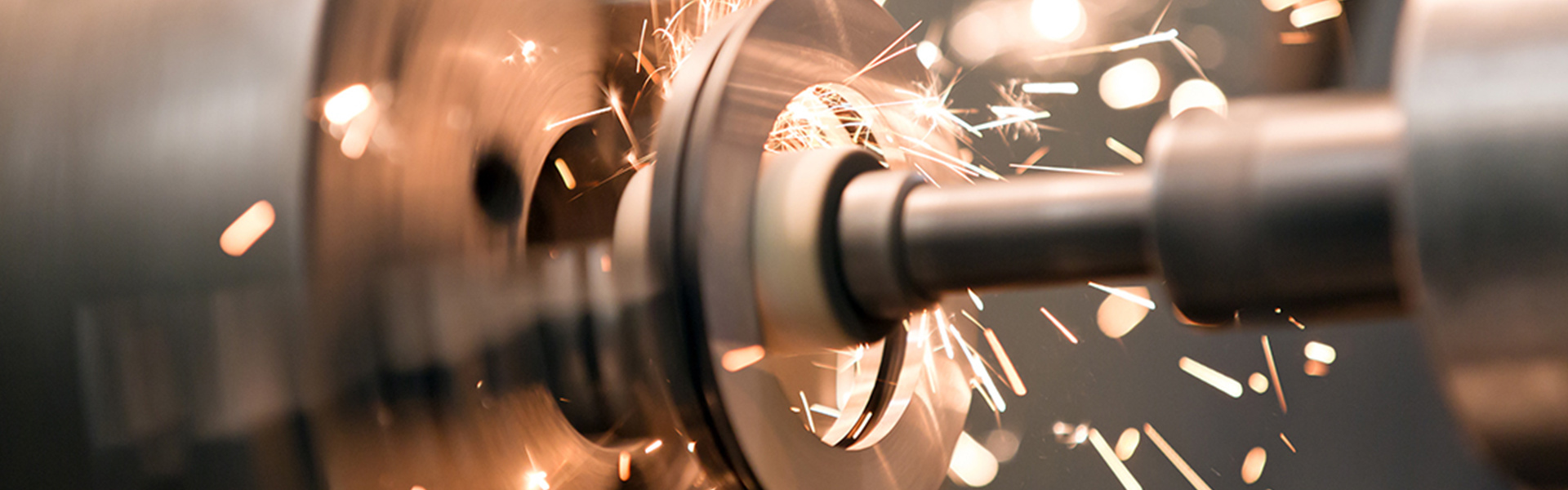

In terms of hardware, there are many kinds of mechanical equipment for the processing of mechanical parts, such as lathe, milling machine, planer, grinder, broaching machine processing center, etc. The inherent processing accuracy of all kinds of equipment is different, so to achieve precision processing, it depends on how high the accuracy of your parts is, and choose the corresponding process route and equipment accordingly;

Now there are many parts processing manufacturers in China, and it is much more difficult to find a suitable processing manufacturer than before. In fact, there are not many differences in technology. The most important thing is the professionalism of the operators during processing, and whether the relevant processing supporting machine tools and product detection equipment are complete. In the process of reprocessing, the relevant parameters of the processed parts should also be paid attention to in real time and adjusted in time. In this way, the probability of reworking products processed by professionals and professional equipment is greatly reduced.

In the field of modern industrial manufacturing, cutting is one of the basic processes with a large amount of applications and a wide range of applications. The cutting methods include punching, shearing, flame cutting, electric discharge machining, water cutting, plasma cutting and laser cutting. Each cutting method has its own advantages, but also has certain limitations.