Navigating the Nuances of Sheet Metal Fabrication: Key Considerations

Understanding Sheet Metal Fabrication

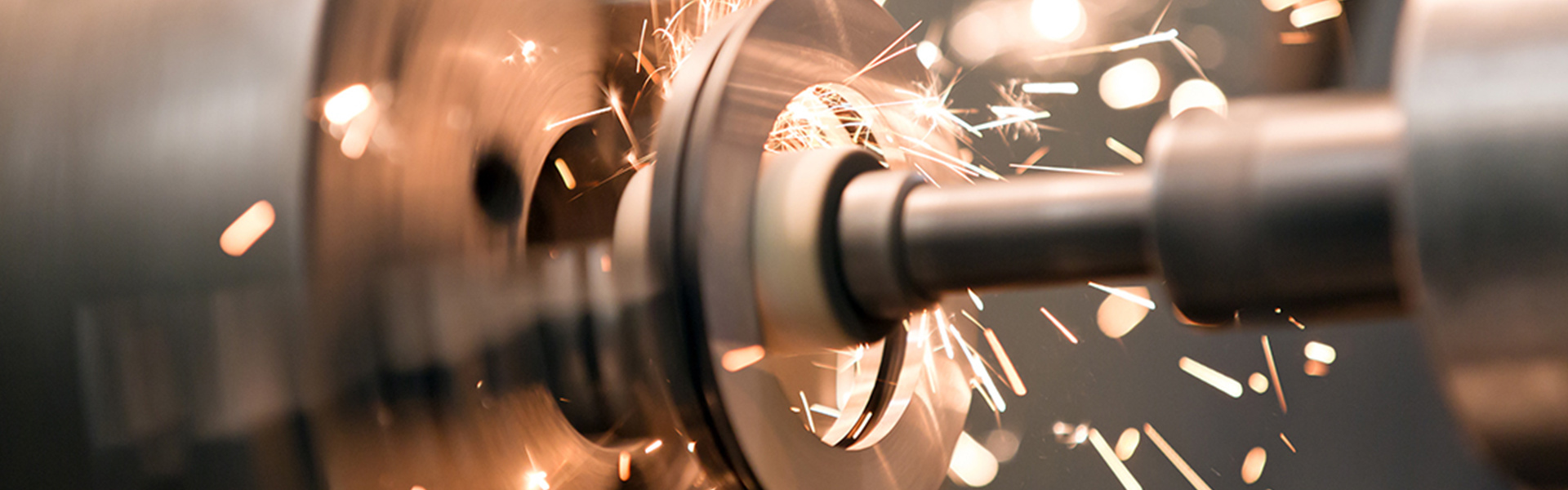

So, you've decided to dive into the world of Sheet Metal Fabrication? Great choice! It's a fascinating field that blends artistry and engineering. But, before you start bending, cutting, or welding, let's chat about some crucial considerations that can make or break your project.

Material Matters

First off, you gotta think about the material. Different metals boast unique properties. For example, aluminum is lightweight and resistant to corrosion, while stainless steel is tough and ideal for a shiny finish. Choosing the right material is like picking the right tool for the job; it can save you headaches down the line. If you're unsure, consult with your supplier to find the best fit for your needs.

Thickness Counts

Now, let's talk thickness. It's not just about how heavy the sheet is; it affects your fabrication methods and overall project durability. Thinner sheets might be easier to work with, but they can sacrifice strength. Conversely, thicker sheets are robust but can be a bear to manipulate. Always have a clear understanding of the specifications required for your project.

Precision is Key

In the realm of Sheet Metal Fabrication, precision isn't just a nice-to-have; it's a must! A millimeter off can throw a wrench in your entire design. Invest in quality tools that ensure your cuts and bends are as accurate as a Swiss watch. Plus, consider using CAD software to visualize your designs before you even touch a sheet!

The Right Tools for the Job

Speaking of tools, let's not forget about them! A well-equipped workshop is half the battle. Whether it's CNC machines, laser cutters, or simple hand tools, having the right equipment can make all the difference. Remember, a carpenter is only as good as his tools—well, same goes here!

Safety First!

Yikes! Safety should always be your top priority. Sheet metal can be sharp and dangerous. Always wear protective gear—gloves, goggles, and perhaps even steel-toed boots. Trust me, you don't want to be the one who neglects this crucial step!

Post-Fabrication Considerations

After you've fabricated your masterpiece, what's next? Finishing touches can make or break the aesthetics and longevity of your project. Consider applying coatings for protection against rust and wear. And, don't forget to check for sharp edges! A little deburring goes a long way in ensuring safety and a professional finish.

Cost-Effectiveness

Let's face it, money matters. While it's tempting to splurge on high-end materials or equipment, always keep your budget in mind. Look for ways to cut costs without compromising quality. Perhaps you can source leftover materials or negotiate bulk pricing with suppliers. Every penny saved can be reinvested into your next project!

Learning from Experience

Finally, don't shy away from making mistakes. Each error is a stepping stone to mastery in Sheet Metal Fabrication. Keep a journal of what worked and what didn't, and don't hesitate to reach out to fellow fabricators for tips. The community is often more than willing to lend a hand!

Conclusion

So, there you have it! Navigating the nuances of Sheet Metal Fabrication doesn't have to be daunting. With the right knowledge and preparation, you can create stunning pieces that are not just functional but also a testament to your skills. Now, roll up those sleeves and get to work!

Related news