Unlocking the Versatility of Sheet Metal Fabrication in Everyday Applications

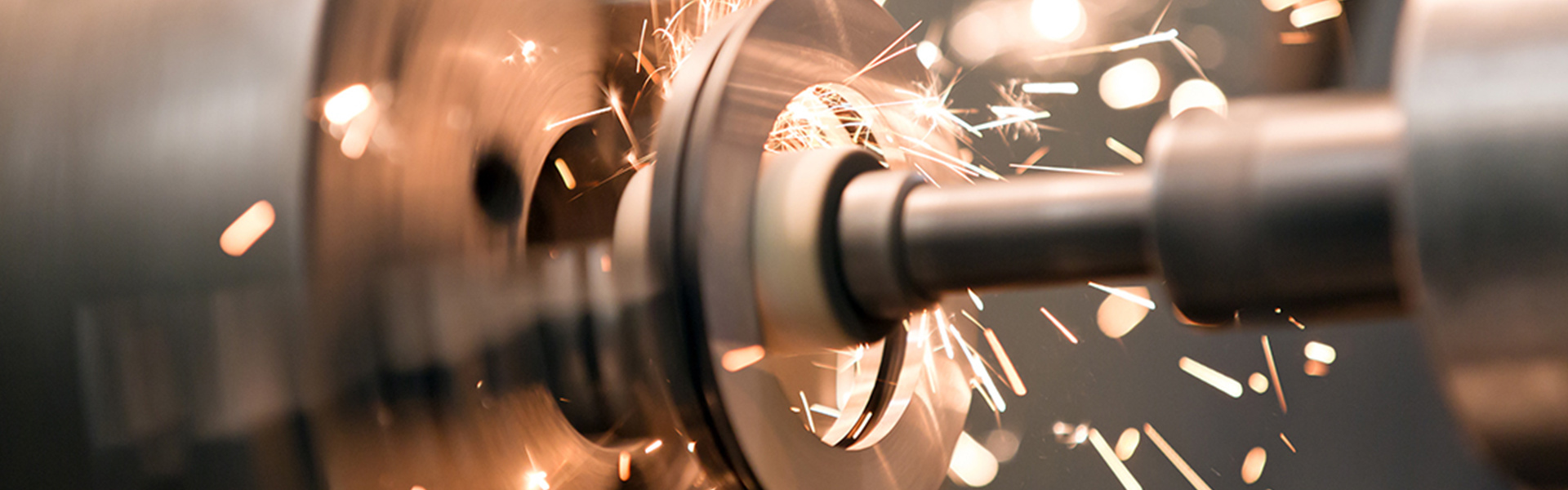

Introduction to Sheet Metal Fabrication

When you think about the stuff that surrounds us, have you ever wondered how they come into being? From the shiny frames of your favorite cars to the robust structures of skyscrapers, one common thread weaves through many industries: Sheet Metal Fabrication. This remarkable process is more than just bending and cutting metal; it's about innovation, versatility, and crafting solutions that stand the test of time!

What is Sheet Metal Fabrication?

Alright, let's break it down! Sheet Metal Fabrication refers to the process of creating metal structures by cutting, bending, and assembling sheet metal. It's like building with Lego, but instead of plastic, you're using various metals like aluminum, steel, and even copper.

A Glimpse into Its Applications

So, where do we see this nifty process in action? Let's take a little tour through some fascinating applications:

1. Automotive Industry

Vroom! The automotive sector is one of the biggest beneficiaries of Sheet Metal Fabrication. Car manufacturers rely on it to produce body panels, frames, and other critical components. The precision involved not only ensures safety but also enhances aesthetics. Ever noticed how a sleek car looks? You guessed it, metal fabrication plays a huge role!

2. Aerospace Engineering

Up, up, and away! In the world of aviation, the weight of materials is crucial. Thus, Sheet Metal Fabrication comes into play, creating lightweight yet strong components for aircraft. Think wings, fuselages, and even the tiniest brackets that hold everything together. Talk about high stakes!

3. Construction Sector

Let's not forget about buildings! Sheet Metal Fabrication is pivotal in the construction industry, where it's used for roofing, ventilation systems, and even decorative elements. You know those shiny skyscrapers? They often owe their stunning façades to expertly fabricated metal sheets.

4. Home Appliances

Ever opened your fridge and marveled at its design? Yup, you guessed it—Sheet Metal Fabrication is involved here too! From the outer casing of appliances to intricate components inside, this process helps create durable, efficient, and stylish home gadgets we can't live without.

The Process: How Does It All Work?

Now, you might be thinking, "How does this magic happen?" Well, the process typically involves:

- Cutting: Using lasers, water jets, or shears to cut the metal into desired shapes.

- Bending: Applying force to create angles and curves without breaking the metal.

- Assembly: Joining pieces together through welding, riveting, or using adhesives.

Why is It Important?

So, why all this fuss about Sheet Metal Fabrication? Well, aside from its versatility, it allows for:

- Cost-Effectiveness: Mass production can lower costs significantly.

- Customization: Easy to tailor designs for specific needs.

- Durability: Metal structures tend to last longer, reducing waste.

Looking Ahead: The Future of Sheet Metal Fabrication

As technology advances, so does Sheet Metal Fabrication. With the rise of automation and computer-aided design, the future looks bright! Imagine robots doing the heavy lifting or AI optimizing designs. Now that's something to get excited about!

Conclusion

To wrap things up, Sheet Metal Fabrication isn't just a process; it's a vital component of modern industry. From cars to homes, it shapes our world in ways we often overlook. So, next time you admire a sleek car or a towering building, remember the magic of metal fabrication behind it. Isn't that cool?

Related news